Boat Storage – Safety and Quality First

Whether you need long-term or short-term storage for your boat, we provide a secure and high-quality space, either on land or in the sea. Our team of experts takes care of your vessel with regular supervision and necessary maintenance services.

Boat Storage Options

1. On-Land Storage – The ideal solution for long-term boat preservation, including:

- Two crane operations (loading and unloading)

- Underwater hull washing

- Drinking water usage

- Electricity for battery charging

- Use of sanitary facilities

- One parking space per vessel

2. In-Sea Storage – Ensuring year-round accessibility for your boat, with benefits including:

- Drinking water usage

- Electricity for battery charging

- Use of sanitary facilities

- One parking space per vessel

Additional maintenance services:

- Battery charging and system check (batteries, valves, bilge area)

- Cleaning and emptying of sewage and bilge tanks

- Anchor rope replacement

- Trailer/boat trolley parking

- Outboard engine storage

General notes

For boats entering the port between 8:00 AM and midnight, the daily mooring fee covers port stay until 12:00 PM the following day.

The shipyard reserves the right to verify vessel dimensions.

If the maximum length or width of the boat exceeds the specified category, the price of the corresponding category will be charged.

Prices are determined according to the overall length of the boat (LOA) based on the current year's price list.

Additional conditions and charges

Use of an electrical connection (16A – 1 socket), water supply, and utilities is included in the mooring fee for transit boats up to 12.99m. For vessels longer than 12.99m, the use of the electrical connection, water tank refilling, and utilities are charged separately.

When washing boats, the use of a water regulator (such as a spray gun) is mandatory.

Boat washing is charged according to the current price list.

A dinghy can be a boat up to 2.5m in length.

Dinghies do not pay for storage if they are on the main vessel. However, if they use separate storage, the user is required to sign a storage and maintenance agreement.

If the main vessel is not on an annual storage contract but only in transit, the daily storage fee for the dinghy is charged according to the current price list.

Storage services are available depending on capacity availability.

Contact us for reservations or additional information!

Boat Maintenance Services

- Application of antifouling paint/coppercoat

- Polishing and washing

- Change of zincs

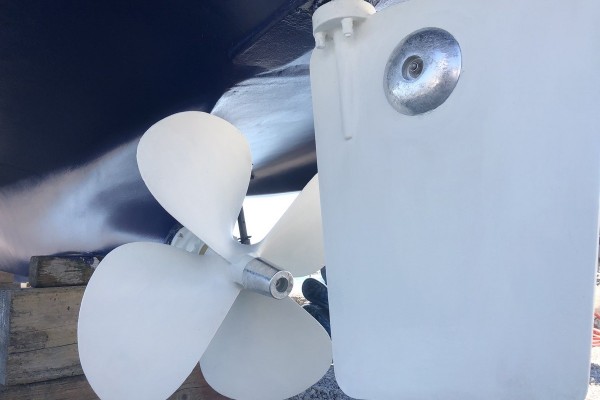

- Cleaning and applying antifouling paint to the propeller and rudder

- Maintenance of teak deck/washing and application of teak oil

- Engine service

- Accommodation of the vessel on land and at sea during and after repairs

- Regular maintenance of the vessel (ventilation of the vessel, washing and cleaning of the interior and exterior of the vessel, regular inspections of the bilge area, etc.)

- Regular engine servicing (engine servicing, clips, zinc replacement, filter replacement, engine winterizing and de-winterizing, tanks, etc.)

- Battery maintenance

- Regular maintenance of the vessel's hull (anti-fouling protection, washing, polishing, etc.)

- Outboard engine servicing

- Installation of a moisture absorber inside the cabin

- Closing the vessel in a plastic sheet

Our professional staff and many years of experience in the maintenance, repair and service of ships, with the application of products of proven reputation from world manufacturers, are a guarantee of the high-quality service that we have been providing for many years.

Our expert team recommends making sure you perform the preventive work listed below before using the vessel:

Complete preparation of the underwater part of the ship

- Renewal of the antifouling coating (antifouling-coppercoat) - Reduces the fouling of the underwater part, reduces the ship's resistance and saves fuel

- Engine cleaning - Reduces the ship's resistance and saves fuel, enables better maneuvering of the vessel

- Replacement of zinc protectors – Ensures the protection of important metal parts of the vessel below the waterline from the action of galvanic currents and corrosion.

- Preventive control of underwater valves - Regular control and replacement of defective valves reduces the risk of the ship sinking, thereby increasing the safety of navigation as well as the risk of death and pollution that would result from the sinking of the vessel itself.

Preparation of the drive motor and equipment

- Full annual engine and drive service - Proper annual maintenance, replacement and inspection of necessary parts ensure proper operation, extend motor / drive life and reduce the possibility of failure

- Battery / Accumulator check - Over time, batteries lose their properties and can let you down when you need them most. By checking the batteries during the preparation of the ship for the summer and eventually charging them, it is ensured that they function correctly throughout the summer and longer.